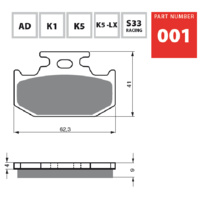

Goldfren K5 Racing pads - Model No 001 K5 - Kawasaki KDX / Suzuki RM / Yamaha Yz

Description

S3 Carbon Ceramic Brake Pads

Free Shipping Australia Wide!

Time to grab yourself a bargain!

We have a huge range of quality Goldfren Disk Brake Pads that we need to sell ASAP, so we are running them out the door at well below retail price! We only have limited stock, so what you see below is all we have so be quick!

Description

The K5 sintered compound is optimal for off-road dirt bikes and ATV. It is recommended for riders who demand great off-road stopping power and brake pad durability when riding on tough off-road terrains. The K5 series is designed for low abrasive interaction with the rotor, long life and self-cleaning capabilities necessary for off-road riding conditions. Friction materials contain metal-ceramic with a sophisticated bronze-graphite and full-metal mixture formulation with fine friction particles to achieve optimal friction properties.

Model Number

001 K5

Need to find the correct pad for your make / model / year bike?

- Click here to view the Goldfren Application guide and scroll down to find your bike and pad number (normally 3 digits)

- Either search for the 3 digit part number in the search bar at the top left of this page, or scroll through the listings in our store

Note: if you are unsure please contact us and we will search for you.

Fitment

CANNONDALE

MMX 400 00 R

KAWASAKI

KX 125 G1/H1/H2/J1/J2/K1 89 – 94 R

KDX 125 A1/A2/B1/B2 90 – 94 R

KDX 200 E1-E6 89 – 94 R

KDX 200 H1-H5 95 – 99 R

KDX 200 SR (DX 200 G) R

KDX 220 R A4-A12/A6F 97 – 06 R

KDX 220 SR (DX 220 B) R

KDX 250 SR (KDX 250 F1) 91 R

KX 250 G1/H1/H2/J1/J2/K1 89 – 84 R

KDX 250 D1 91 – 93 R

KLX 250 R D1/D2/G1 93 – 97 R

KLX 250 F1-F4 94 – 97 R

KX 500 E1-E7 89 – 95 R

KLX 650 C1-C3 93 – 97 R

SUZUKI

TS 125 RK/RL/RM/RN/RP/RR 90 – 96 R

RM 125 K/L/M 89 – 91 R

TS 200 RK/RL/RM/RN/RP/RR 89 – 94 R

DR 250 RS/RLS/RT/RV/RLV/RLW/RW/RY

(SJ45A/DOHC) 95 – 00 R

DR 250 RXT/RXLT/RXV/RXLV/RXW/

RXLW//RXGW/RXGLW/RXY/

RXGY/(Dejbel 250 XC/GPS

Ver (SJ45A) R

DR 250 SL/SM/SN/SEP/SER/SES (SJ44A) 90 – 95 R

RM 250 K/L/M 89 – 91 R

RMX 250 K/M/N/P 89 – 93 R

RMX 250 T/V/W 96 – 98 R

DR 350 SL/SM/SN/SP 4 bolt front disc/

kick start 90 – 93 R

DR 350 SER/SES (Elektric start/

4 bolt front disc) 94 – 95 R

DR 350 SET/SEV (Elektric start/

4 bolt front disc) 96 – 97 R

DR 350 SEW/SEX (Elektric star/

6 bolt front disc 98 – 99 R

DR 650 SET/SEV (Elektric start/

4 bolt front disc) 96 – 97 R

YAMAHA

DT 125 RE 05 – 07 R

DT 125 X 05 – 06 R

YZ 125 A/B 90 – 91 R

TT 250 RL/RM/RN/RP/RR/RS 99 – 04 R

XG 250 Tricker (5XT1) 04 – 06 R

XT 250 X (3C51/2) 05 – 08 R

XTZ 250 Lander (Brazil) (4B41/2) 07 – 08 R

YZ 250 A/WRA/B 90 – 91 R

WR 200 D/E/F 92 – 94 R

WR 250 ZB/ZD/ZE/ZF/ZG/ZH/ZJ 91 – 97 R

YZ 400 FK 98 R

WR 500 ZD 92 R

TT 600 RES 04 R

TT 600 K (4LW1/4GV1/4LW2)

Up to 4GV 003403

(Nissin rear caliper) 93 – 95 R

Features

- High static friction coefficient

- Good abrasive resistance

- Thermal stability up to 500°C, and even up to 750°C over a short term

- Self cleaning capability

- Low abrasive interaction with the brake rotor material

- Three(3) times +/- longer operational life compared to organic and Kevlar composite materials

Range of Application

- Developed for off-road because it features long life on heavy-duty terrains

- On off-road bikes and ATV

- Can be used on both front and rear brakes. Hot and dry weather, use only on rear brake

- Could be used on the rear brake of road racing motorcycles

Materiel Operating Parameters

- Specific pressure: P < 2.0 Mpa

- Sliding velocity: V < 20 m.s-1

- Constant maximum temp: 500°C

- Short time maximum temp.: 750°C

- Counter-surfaces: steel disks

General Characteristics about Goldfren Brake Pads

- All the GOLDfren brake pads are made with sintered metal-ceramic and ceramic-carbon friction materials

- Sintered brake pads offer no brake fade when operating at high temperatures and in wet conditions

- Sintered brake pads provide superior stopping power and longer life compared to other brake pad types such as: carbon organic, organic, or semi-metallic organic

- Sintered brake pads are made by fusing together metallic particles under high temperatures and pressure using a pressed powdered-metal technology

- GOLDfren is a pioneer in sintering, using advanced and progressive powder metallurgy methods

- Designed for both wet and dry applications

- Sintered brake pads deliver exceptional braking performance and durability under the most demanding conditions

- All the materials used are lead and asbestos free

- GOLDfren® is the brand for high-end quality aftermarket performance disc brakes

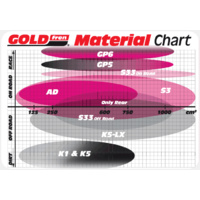

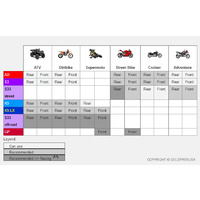

- Compound series available are: AD, S3, K1, K5, K5-LX, S33, GP5, GP6, PG7

- Application of each compound is based on our brake pad application chart or the rider's preference and riding style

- The sintered friction material is soldered to the copper lined steel backing plate, hence, separation (which can happen with organic pads) is virtually impossible

Notes

- Replacement of brake pads should be done in dry clean conditions and preferably by a professionally qualified person. If the friction material comes in contact with oil or brake fluid and the liquid soaks into the pores of the friction material, a catastrophic decrease in friction coefficient (braking performance) could occur

- Please beware that sintered brake pads require a bed-in period after installation. Allow some extra braking distance during the bed-in period. For more information on bedding your brake pads see our FAQs page #6

- Braking performance is significantly influenced by the quality of the braking surface of the Disc rotor; also by the age and quality of the brake fluid, and by the correct choice of complementary type of brake pad

- To achieve the perfect brake effect, we recommend using GOLDfren brake pads in conjunction with GOLDfren rotors and brake lines because of its excellent quality common friction properties

- Brake with the products developed by GOLDfren®

Please note: You will need to order 1 set per caliper for Twin Disk front end. If you have twin rotors you will need to order 2 X sets of pads.

Please note: we only have limited stock and it is all listed on this site.

Please note: Product photos may not represent the exact shape of the pad listed - please check the technical drawing above for exact pad shape.

Bedding-in: this is a particularly important procedure for all compounds. The pads are bedded in by applying the brakes lightly several times and ending with a firm bite, leaving a pause between one squeeze and the next. This will produce the correct heating and cooling cycle needed to prepare the system. The duration of the bedding-in period depends on the type of compound: generally longer for organic compounds than for sintered.

Specifications

| SKU | 001K5 |

| Brand | Goldfren |

| Shipping Weight | 0.3000kg |

| Shipping Width | 0.150m |

| Shipping Height | 0.100m |

| Shipping Length | 0.030m |

| Shipping Cubic | 0.000450000m3 |

Reviews

Be The First To Review This Product!

Help other motospares users shop smarter by writing reviews for products you have purchased.

More From This Category

$34.95

or 4 payments of $8.74 with

Info

Info

Goldfren S3 Racing pads - Model No 231 S3 - Aprilia / Husaberg / KTM

$34.95

or 4 payments of $8.74 with

Info

Info

Goldfren S3 Racing pads - Model No 167 S3 - Yamaha YZ80 86-01 / YZ85 02-16

$34.95

or 4 payments of $8.74 with

Info

Info

Goldfren S3 Racing pads - Model No 018 S3 - Honda / Sachs / Yamaha

$34.95

or 4 payments of $8.74 with

Info

Info

Goldfren S3 Racing pads - Model No 034 S3 - Yamaha YZ80 86-01 / YZ85 02-16

$34.95

or 4 payments of $8.74 with

Info

Info

Goldfren S3 Racing pads - Model No 248 S3 - Yamaha YZ450 / 250 / 125 / WR450

$34.95

or 4 payments of $8.74 with

Info

Info

Goldfren S3 Racing pads - Model No 016 S3 - Hyosung / Kawasaki / Suzuki

$34.95

or 4 payments of $8.74 with

Info

Info

Goldfren K5 Racing pads - Model No 096 K5 - Aprilia / Cagiva / KTM

$34.95

or 4 payments of $8.74 with

Info

Info